- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

China Full-Automatic Wires Dual Head Machinery Manufacturers, Suppliers, Factory

It is a good way to improve our products and service. Our mission is to develop creative products to customers with a good experience for Full-Automatic Wires Dual Head Machinery,Full-Automatic Wires Dual Head Equipment,Full-Automatic Wires Dual Head production line,Full-Automatic Wires Dual Head Machine,Automatic Wires Dual Head, As a key enterprise of this industry, our corporation makes endeavours to become a leading supplier, dependant on the faith of expert quality & all over the world provider.

Full-Automatic Wires Dual Head Machinery, Wide selection and fast delivery to suit your needs! Our philosophy: Good quality, great service, keep improving. We are looking forward that more and more oversea friends join in our family for further development near the future!

Hot Products

Electric Tapping Machine

High quality Electric Tapping Machine is offered by China manufacturer YueLi. Quanzhou Yueli Automation Equipment Co., Ltd. was founded in 2013 and is located in Nan'an, Fujian, the hometown of water heating in China.320 Four-axis CAM Turntable

YueLi is 320 Four-axis CAM Turntable manufacturer and supplier in China.Drilling And Tapping Machine

As one of professional manufacturer in China, YueLi would like to provide you Drilling And Tapping Machine. And we will offer you the best after-sale service and timely delivery.Automatic Polishing Machine

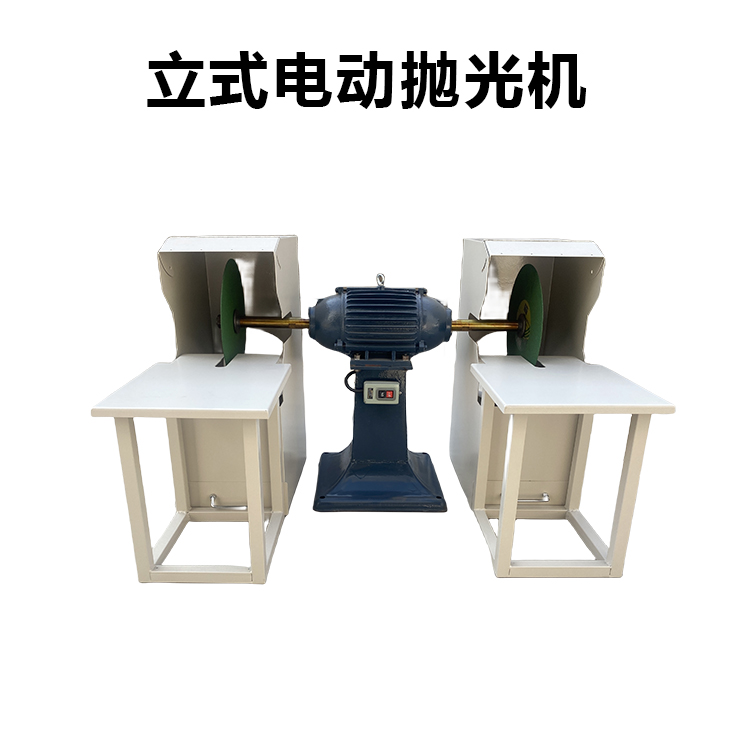

YueLi is one of Automatic Polishing Machine manufacturer and supplier in China. We can provide professional service and better price for you. We follow the quality of rest assured that the price of conscience, dedicated service.Vertical Electric Polishing Machine

Vertical Electric Polishing Machine is a power tool, polishing machine is composed of base, throw plate, polishing fabric, polishing cover and cover and other basic components. The key to the operation of the polishing machine is to try to get the maximum polishing rate in order to remove the damaged layer caused by grinding as soon as possible. At the same time, the polishing damage layer should not affect the final observed tissue, that is, it will not cause fake tissue. The former requires the use of coarse abrasive to ensure that the abrasive belt polishing machine has a large polishing rate to remove the polished damage layer, but the polishing damage layer is also deep; The latter requires the use of the finest material, so that the polishing damage layer is shallow, but the polishing rate is low.