- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

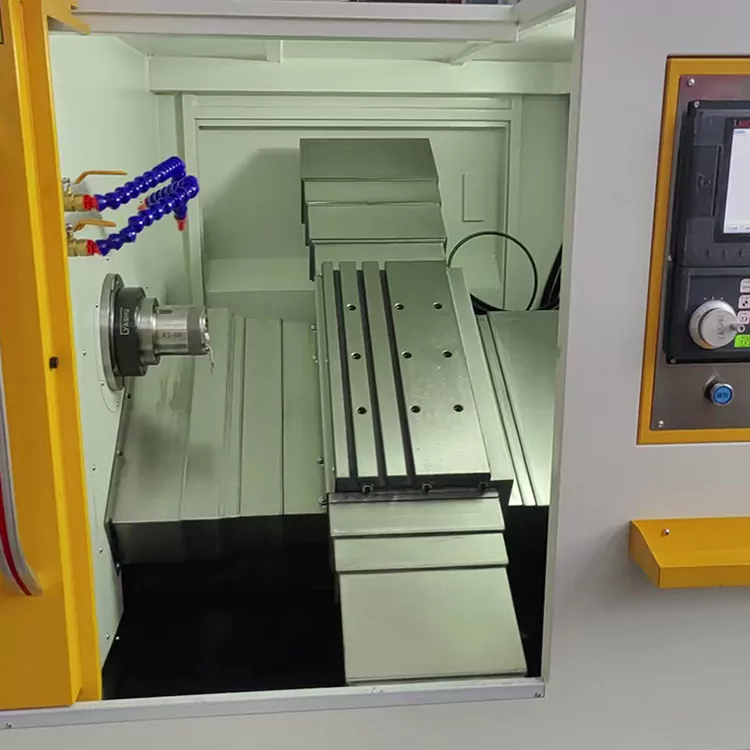

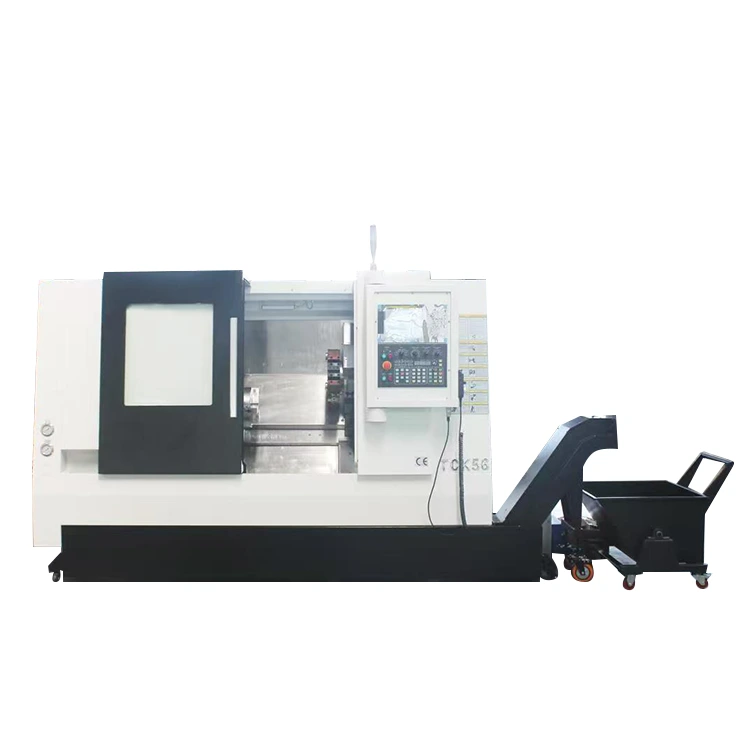

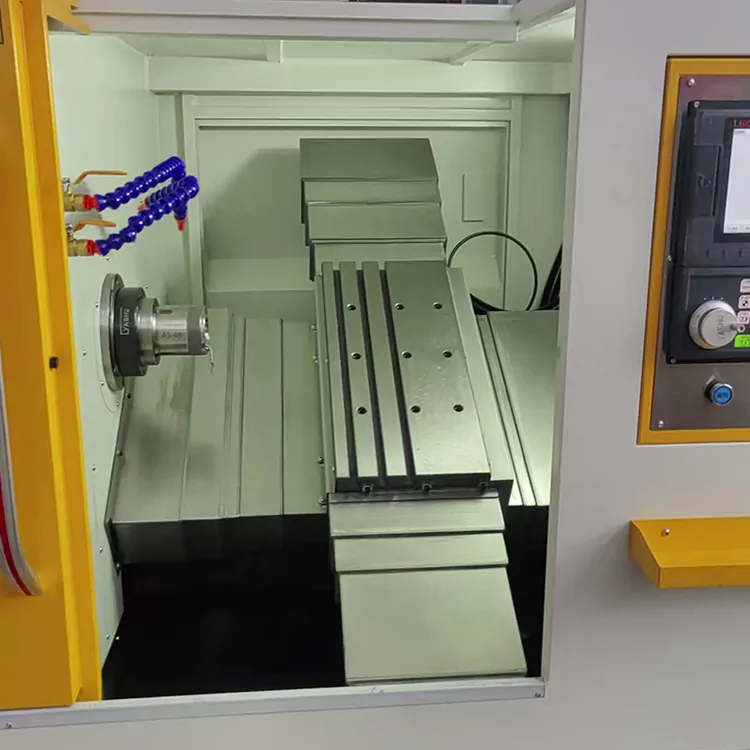

Type CNC lathe

It is suitable for mass production of copper, iron, aluminum, stainless steel bar within 35mm, and automatic mass production of forging parts and other pellets within 50mm. With a number of patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a unilateral cutting amount within 2mm, precision tolerance within ±0.01mm and finish degree of 1.6. Widely used in the upgrading of hard rail CNC lathes, CAM automatic lathes and hydraulic lathes, to achieve automated production to save labor costs and improve product quality.

Model:YL-36J

Send Inquiry

Product Description

It is suitable for mass production of copper, iron, aluminum, stainless steel bar within 35mm, and automatic mass production of forging parts and other pellets within 50mm. With a number of patented technologies such as high rigidity and anti-deformation structure, it is suitable for processing products with a unilateral cutting amount within 2mm, precision tolerance within ±0.01mm and finish degree of 1.6. Widely used in the upgrading of hard rail CNC lathes, CAM automatic lathes and hydraulic lathes, to achieve automated production to save labor costs and improve product quality.

| Project | Technical parameters | Maximum value |

| Through hole diameter | Phi is 35 mm | Phi is 36mm |

| Accuracy tolerance | +/-0.01mm | |

| Finishing finish | 1.6 RA | |

| One side cut amount | 2mm | 3mm |

| Spindle speed | 3500r/min | 4000r/min |

| Particle clamping diameter | Phi is 40 mm | Phi 50mm |

| Machining length | 230mm | |

| X-axis stroke | 600mm | |

| Z-axis stroke | 230mm | |

| Fast shift speed | 20m/min | 30m/min |

| Roundabout diameter | Phi 350 mm | |

| The center of the tool rest is high | 40mm | |

| Finish length with buttress | 120mm | |

| Square knife specifications | 16mm | |

| Mechanical speci | fications | |

| Specifications | Parameters | Brand |

| Bed form | 30°slanted bed | |

| Cutter form | Row knife | |

| Guide form | 25 linear guide | Taiwan |

| Screw rod |

25 Ball grinding precision grade |

Taiwan |

| Spindle unit | Homemade high speed paired bearing unit spindle |

Wuxi two-axis (bearing) |

| Spindle nose form | A2-4 | |

| Base form | Heavy duty anti-deformation patent stand | Self-develaped |

| Ground to spindle center height | 1080mm |

Hot Tags: YL-36J Type CNC lathe, China, Suppliers, Manufacturers, Factory, Price, Quality, Quotation

Related Category

Send Inquiry

Please Feel free to give your inquiry in the form below. We will reply you in 24 hours.