- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

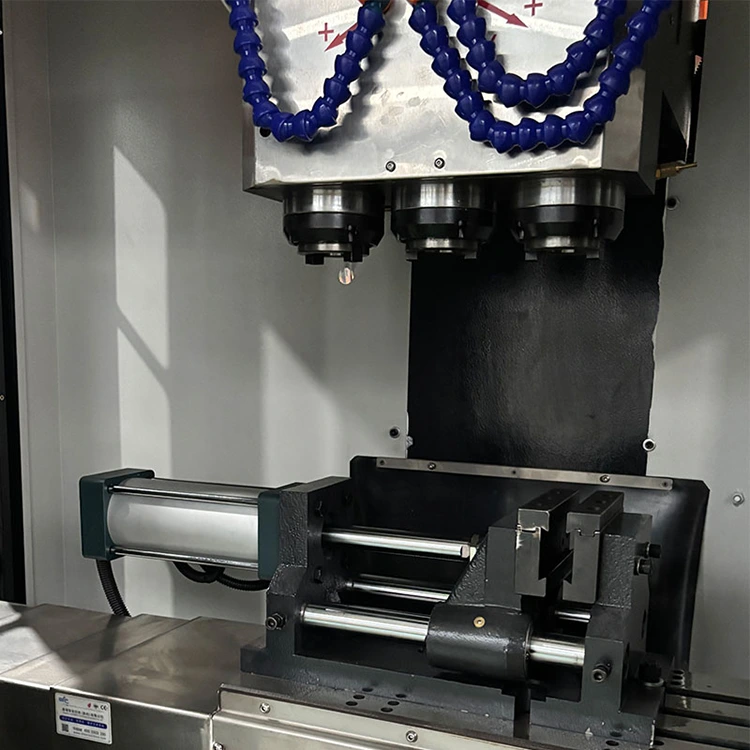

Vertical 3-Axis CNC Compound Machine

Send Inquiry

As a professional manufacturer, YueLi is pleased to offer you a high-quality Vertical 3-Axis CNC Compound Machine, which is equipped with a Taiwan Yitu bus CNC system and a touch screen for intuitive programming and easy operation. The worktable and middle support are equipped with HIWIN roller linear guides and ball screws, enabling heavy-duty cutting. Please feel free to contact us at any time.

Product Features

1. The YueLI high-quality Vertical 3-Axis CNC Compound Machine features three-axis CNC functionality, allowing for drilling, tapping, and milling operations along each axis.

2. Equipped with a high-precision transmission mechanism and intelligent power system, it achieves rigid and powerful cutting and stepless speed regulation, ensuring precise and stable dimensions of the processed parts.

3. Key pneumatic components utilize imported Korean pneumatic elements, ensuring quick response and durability.

4. CNC positioning technology provides the Vertical 3-Axis CNC Compound Machine with memory and reproduction capabilities for repeatable positioning accuracy, and the tool change process is highly automated, significantly reducing process cycle time.

5. The user-friendly interface supports single-person monitoring of multiple machines, significantly reducing labor input and workload.

6. The entire machine is equipped with a fully sealed protective cover, effectively isolating processing debris and maintaining a clean and orderly production environment.

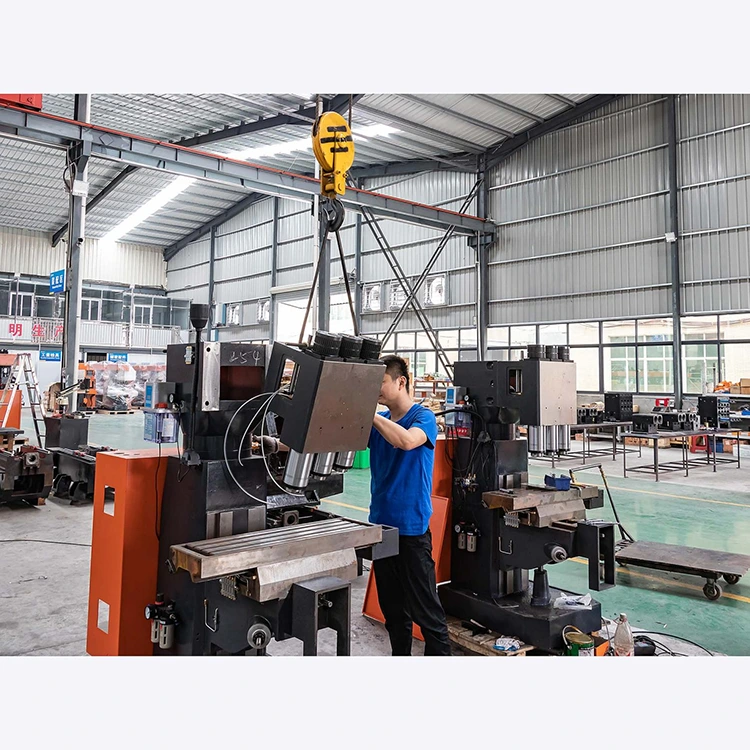

Process Production

1. Cast iron undergoes high-temperature annealing and aging treatment for more than six months.

2. Rigorous assembly process (linear guide assembly, ball screw assembly, bearing assembly, etc.).

3. Exquisite scraping process (motor base scraping, spindle end face scraping, column mounting surface scraping).

4. Scientific production and manufacturing, with a traceable quality control system throughout the entire process.

Quality Assurance

1. During pitch error detection, the straightness of the linear guides in both the XX and YY directions can be simultaneously detected, ensuring the processing and assembly accuracy of each component of the machine tool. The actual positioning accuracy and repeat positioning accuracy of the machine tool are measured.

2. The perpendicularity of the spindle and the working plane is tested for the entire machine, requiring an accuracy of within 0.03mm.

3. The perpendicularity of the Z-axis guide and the worktable is tested for the entire machine, requiring an accuracy of within 0.03mm.

4. The perpendicularity of the XY-axis guides is tested for the entire Vertical 3-Axis CNC Compound Machine, requiring an accuracy of within 0.01mm.

Product Parameter

|

Name specification parameter name |

50 three-axis linear rail |

|

ZSK 530 |

|

|

Maximum travel of X-axis (screw) mm |

400mm |

|

Y-axis maximum travel mm |

280mm |

|

Spindle sleeve diameter mm |

105mm |

|

Spindle taper |

BT40 |

|

Z1/Z2/Z3/Z4 maximum stroke mm |

110mm |

|

Spindle distance mm |

120mm |

|

Spindle end to work table mm |

250/500mm |

|

Distance between spindle axis and bed guide rail mm |

250 |

|

Maximum drilling diameter mm |

50mm |

|

Maximum tapping diameter mm |

50mm |

|

Spindle speed r/min |

0-3000r/min |

|

Spindle motor power KW |

5.5KW |

|

Overall dimensions LWH: |

1700*1850*2250 |

|

Machine tool net weight KG |

1600KG |

Processed Product Display:

Application Fields

Vertical 3-Axis CNC Compound Machine is capable of completing metal cutting of copper parts, aluminum parts, zinc alloys, and steel parts, and is suitable for industries such as plumbing and sanitary ware, fire-fighting valves, door control hardware, household appliance hardware, water meter & auto/motorcycle parts, and aerospace.