- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

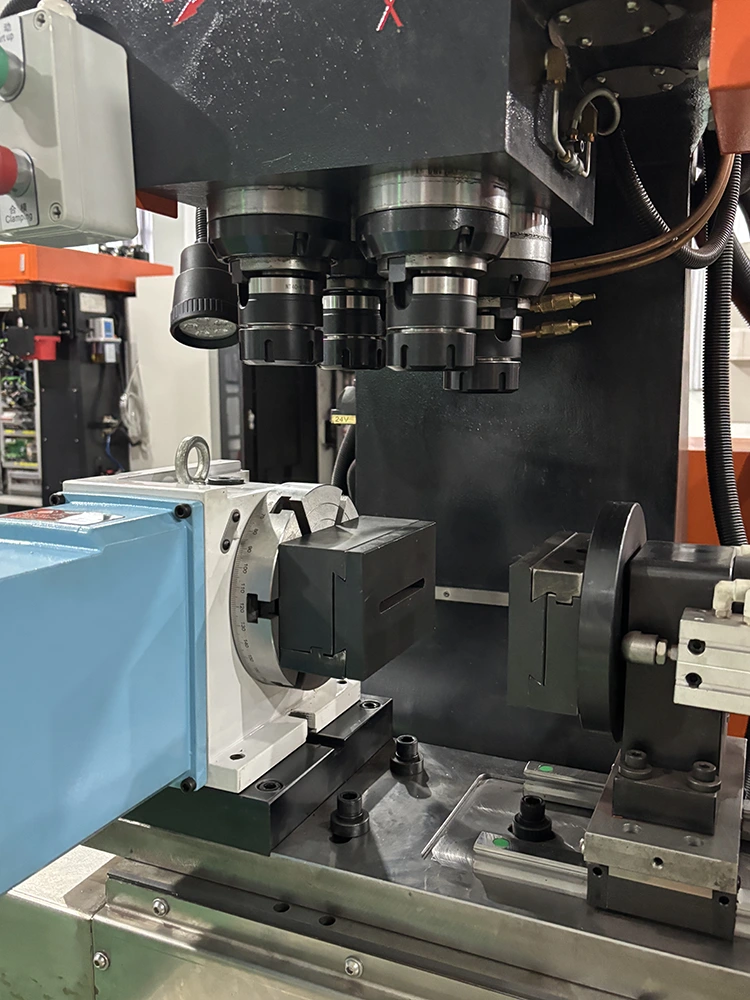

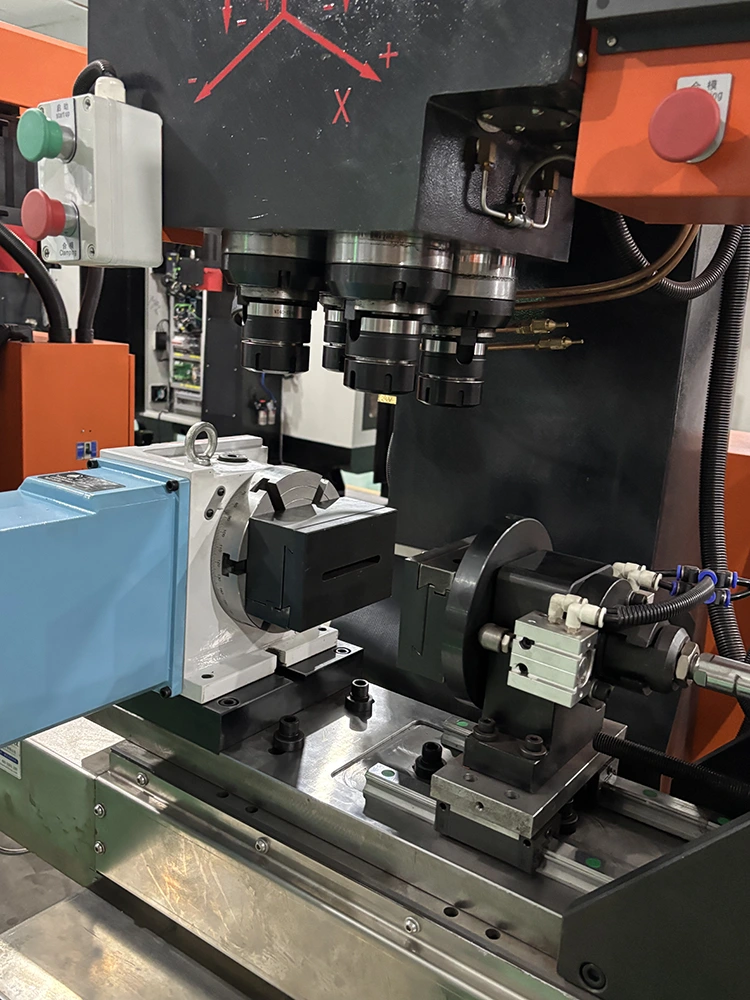

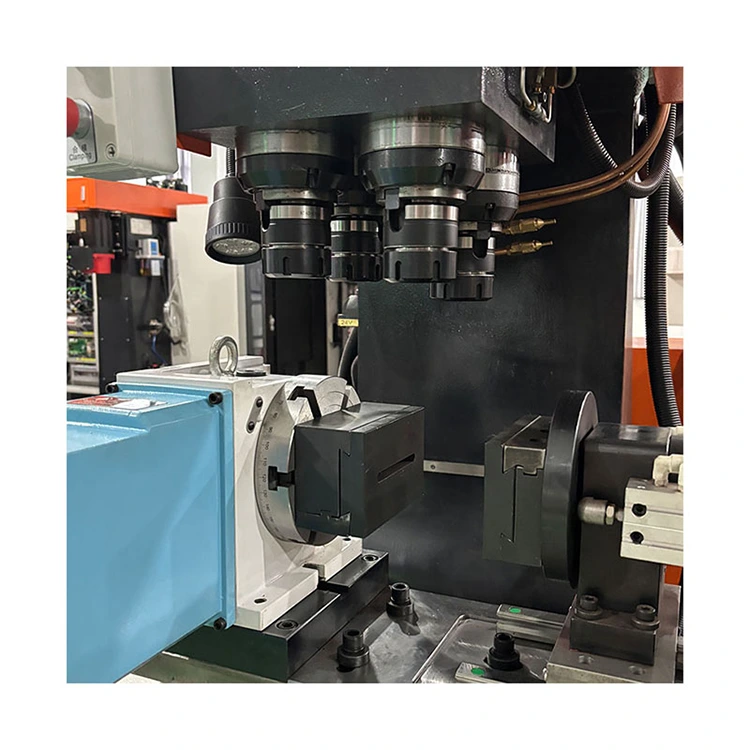

Multi-Function 4 Spindle Drilling Tapping Compound Machine

Send Inquiry

Product Features

1. All four spindles of the YueLi high quality Multi-Function 4 Spindle Drilling Tapping Compound Machine are equipped with high-power motors and can operate independently. The lead screws use ball screws to ensure stable and precise operation. The speed can be adjusted at any time, ensuring accuracy in repetitive machining.

2. The cast iron bed has undergone more than six months of natural aging treatment, ensuring excellent stability. The workbench guide rails and lead screws are heavy-duty designed, preventing shaking even when machining heavy materials. Key components are hand-scraped by experienced technicians to ensure a perfect fit of all parts.

3. The Multi-Function 4 Spindle Drilling Tapping Compound Machine uses a Taiwan Yitu control system, which is easy to operate with just a touch of the screen. The button icons are intuitive and easy to understand, allowing even beginners to learn how to use it within half a day. Commonly used machining programs are pre-saved and can be switched with one click when changing products.

4. The entire machine is tightly sealed, effectively preventing metal chips, oil stains, and coolant leakage. Korean pneumatic components provide sensitive response and significant emergency braking effect. Opening the protective cover automatically stops the machine's operation, ensuring safety.

Product Parameter

|

Parameter Name |

Spec |

|

Max Travel of X-Axis (Ball Screw)mm |

400mm |

|

Max Travel ofY-Axis (Ball Screw)mm |

280mm |

|

Spindle sleeve diameter |

105mm |

|

Spindle tap |

BT40 |

|

Max Travel of Z1/Z2/Z3/Z4, mm |

135mm |

|

Spindle Center Distance mm |

120mm |

|

Distance from Spindle End Face to Worktable Surface mm |

250/500mm |

|

Distance from Spindle Axis to Bed Guideway Surface mm |

250 |

|

MAX drilling diameter mm |

50mm |

|

Max tapping diameter mm |

50mm |

|

Spindle speed r/min |

0-3000 r/min |

|

Spindle motor power KW |

5.5KW |

|

Overall Dimensions (L×W×H): |

1700×1850×2250 |

|

Machine Net Weight, kg |

1600KG |

Quality Inspection

Before leaving the factory, the Multi-Function 4 Spindle Drilling Tapping Compound Machine is repeatedly tested using laser equipment to ensure the straightness and levelness of the guide rails are flawless. The machine tool has a built-in error compensation function, maintaining accuracy even after long-term use. High repetitive positioning accuracy ensures that tool changes do not affect accuracy.

Product Application

It is capable of completing metal cutting of copper parts, aluminum parts, zinc alloys, and steel parts, and is suitable for industries such as plumbing and sanitary ware, fire-fighting valves, door control hardware, household appliance hardware, water meter & auto/motorcycle parts, and aerospace.