- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

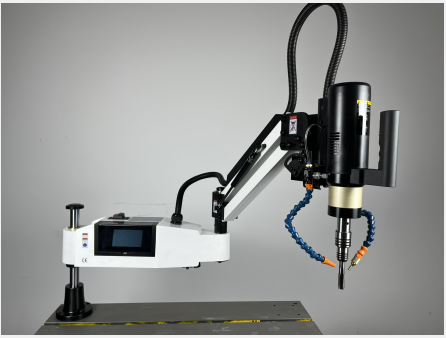

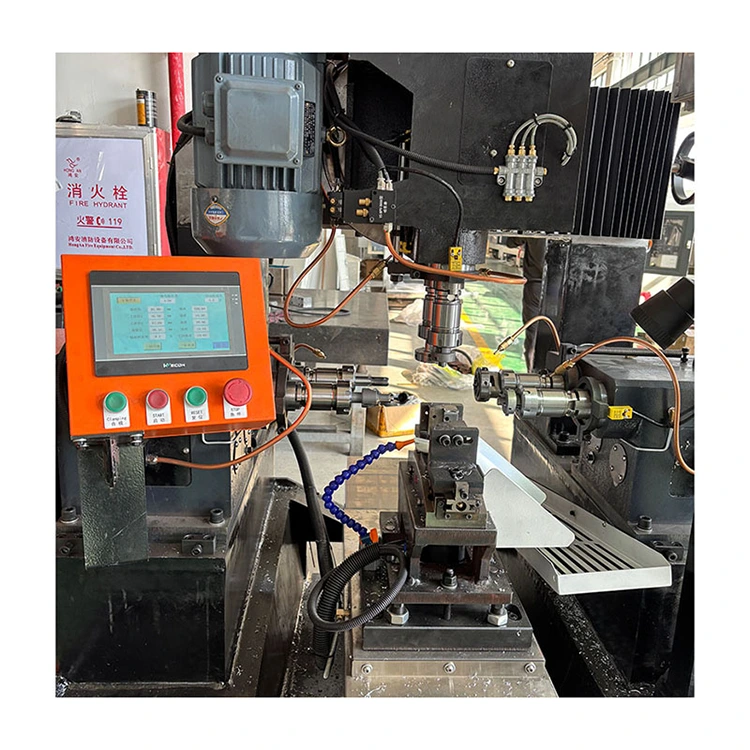

Auto Drilling Tapping Machine

Send Inquiry

Servo electric offensive machine: lightweight, flexible, efficient, and the advantages of other similar devices that cannot be replaced. The new servo electric attack machine has functions such as intelligent and deep, free regulating torque. Avoid the limitations of lathes, drilling machines or manual attacks, saving time, effort, not easy to rot teeth, and taps are not easy to break.

Auto Drilling Tapping Machine Features:

Manual attack wire mode: Manual Tapping Mode

Automatic attack silk mode: Automatic Tapping Mode

Deep hole processing mode: · Deep Hole Machine

Workpiece storage function: Workpiece Storage Function

Thousand direction level attack: Universal Horizontal Tapping

Outer thread plate tooth attack wire:

Facking function:

Tap extension rod attack wire

Twist mode

Optional attachment

| Name | Universal | Single Spray Oil | Double Fuel Injection | Blew | Three -section Arm | Lift |

| Price | 200 | 300 | 400 | 300 | 600 | 200 |

The main parameters:

| Model | YL-M10C | YL-M12C | YL-M16C | YL-M20C | YL-M24C | YL-M30C |

| Input Voltage | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ | 220V/50HZ |

| Rated Power | 600W | 600W | 600W | 600W | 1200W | 1200W |

| Scope | M3-M10 | M3-M12 | M3-M16 | M3-M20 | M3-M24 | M3-M24 |

| Way Of Working | Vertical /vertical horizontal | |||||

| Work Radius | 1045mm | 1045mm | 1045mm | 1045mm | 1045mm | 1045mm |

| Maximum Speed | 1200rpm | 660rpm | 375rpm | 240rpm | 550rpm | 200rpm |

| Package Size | 700*660*220mm | 700*660*220mm | 700*660*220mm | 700*660*220mm | 700*660*220mm | 700*660*220mm |

| Equipment Weight | 31kg | 31kg | 31kg | 31kg | 52.5kg | 52.5kg |

Applicable field

Subsidable electric shock machine applicable workpiece materials: can be easily attacked Silk operation.

The application of servo electric attack machine:

It is suitable for all mechanical manufacturing industries, machine tools, mold machinery, plastic machinery, printing machinery, packaging machinery manufacturers, engineering machinery, automotive motorcycle parts, aviation engines, locomotive vehicles, tobacco machinery, and universal machinery.

The main preparation of servo electric shock machines: servo motor (OKERS), servo driver system, high -definition human aircraft interface, precision planet reducer, high -precision bearing bracket, high -strength fixed seat, safety torque protection clip, electric box, sandwich head A dedicated wrench and one power cord.

Product advantage: This machine surpasses the technical advantage of similar products

1. Microcomputer control, automatic setting of motor torque of the motor, the blind hole is constantly tap: you can set the motor output torque according to the size of the attack wire, plus the overload protection of the torque clip, double protection, and constantly tap;

2. Intelligent deeper, automatically attack, automatically return. There are three types of attack wire modes of the manual mode standard tooth automatic mode, the standard tooth automatic mode is free to switch, the operation is simplified, intelligent, and human.

(1) Manual mode: two buttons can achieve fast attack wire;

(2) Standard tooth automatic mode: You only need to know that the tap of M several can achieve automatic control depth and lead the peer technology.

(3) Non -dental automatic mode: All types of taps can automatically control the depth of the dental distance.

3. You can attack again to the end, or you can attack the repeated mode of a few laps and then attack and then retreat.

4. High -efficiency, continuous use of barrier -free, one to several ordinary attack machines;

5. The Taiwan factory is made in the Taiwan factory. The gear has increased, lengthened, added, durable, and highly precise.

6. High accuracy, thick, strong strength;

7. The scope of work activities is large, and the heavier workpiece does not need to move;

8. Stable performance, continuous use of barrier -free;

9. After -sales has a guarantee product for 12 months. The 7 -day work system of the after -sales department solves the problem at the fastest speed, and minimizes the loss of client's misunderstanding.