- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

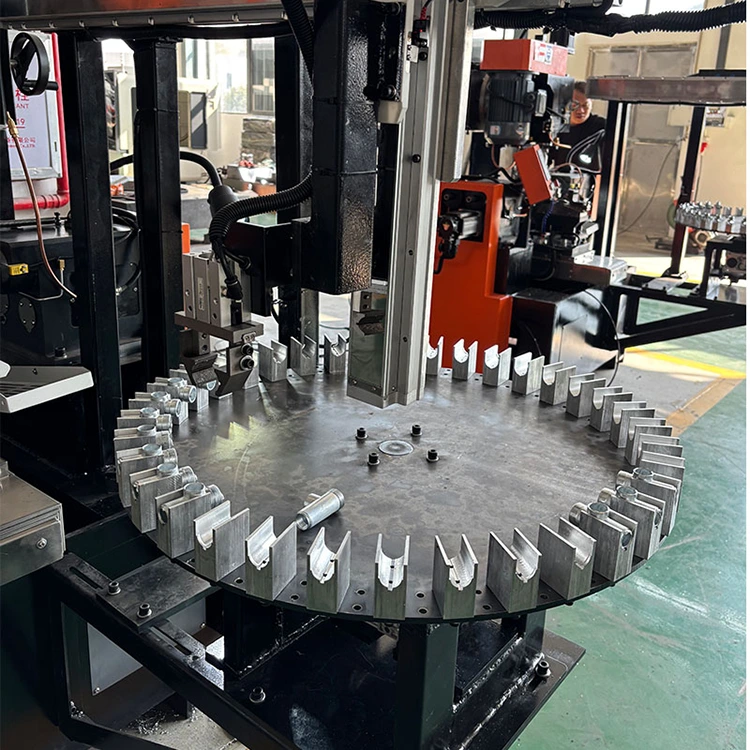

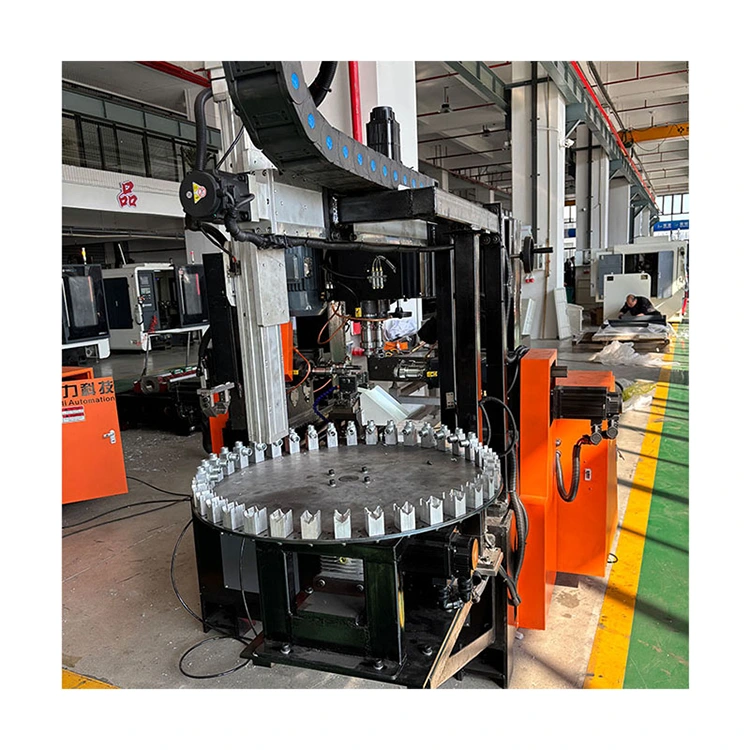

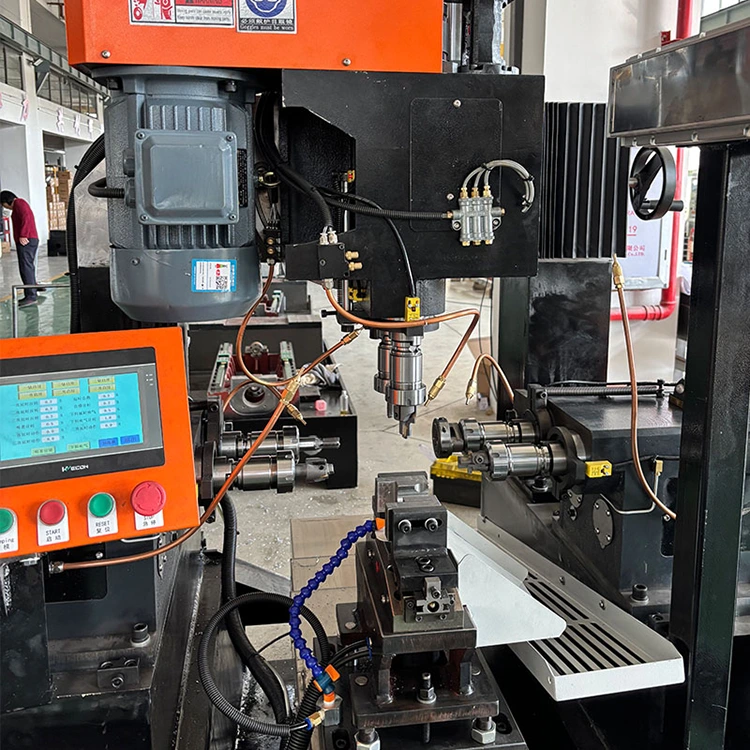

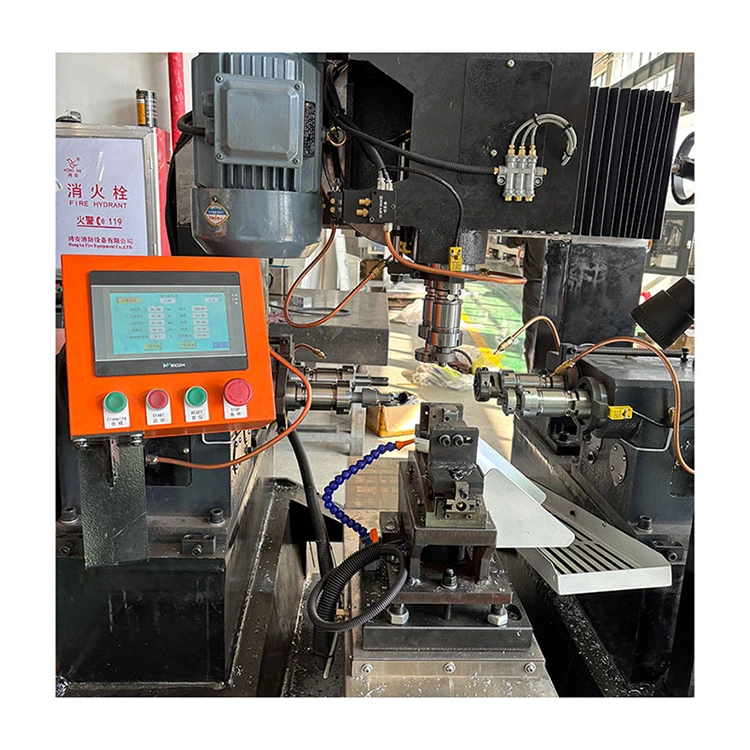

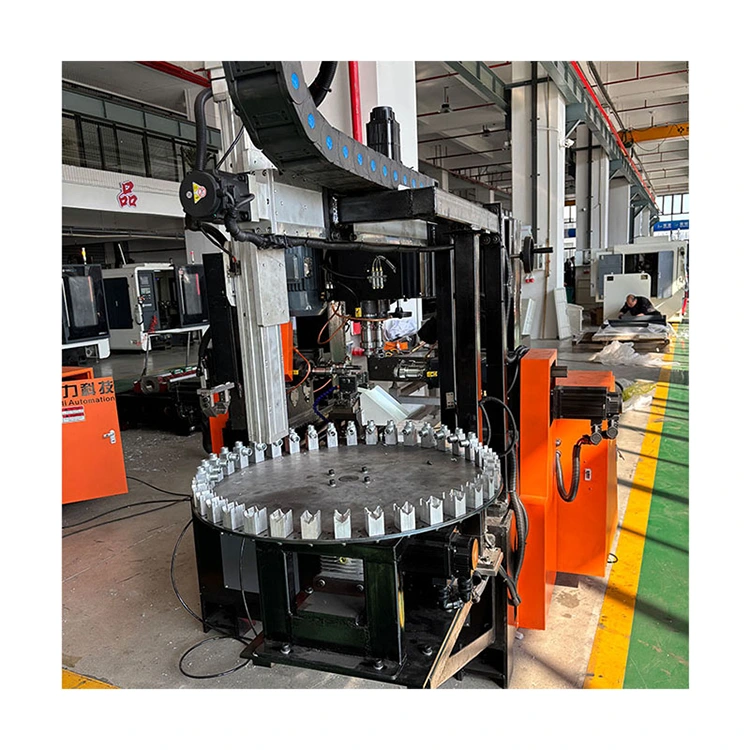

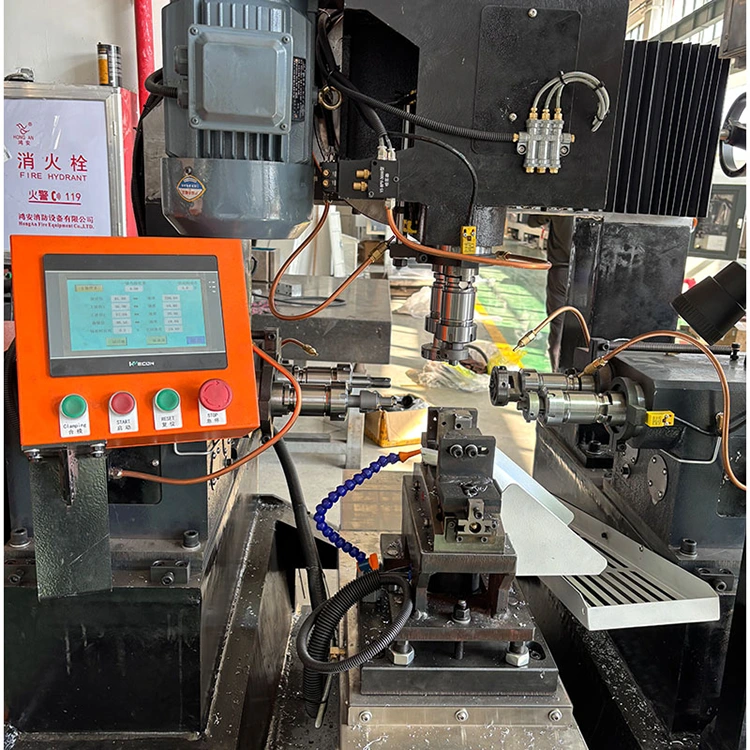

CNC Auto Rotary Drilling Tapping Machine

Send Inquiry

As a China factory focusing on R & D and production of composite processing equipment, Yueli has always been committed to providing customers with products that can create real value. This durable CNC Auto Rotary Drilling Tapping Machine perfectly embodies our design philosophy: combining rigidity, precision and automation, designed for customers who require high-volume, multi-hole, high-consistency machining tasks, helping you achieve your core goal of cost reduction and efficiency.

What does it do?

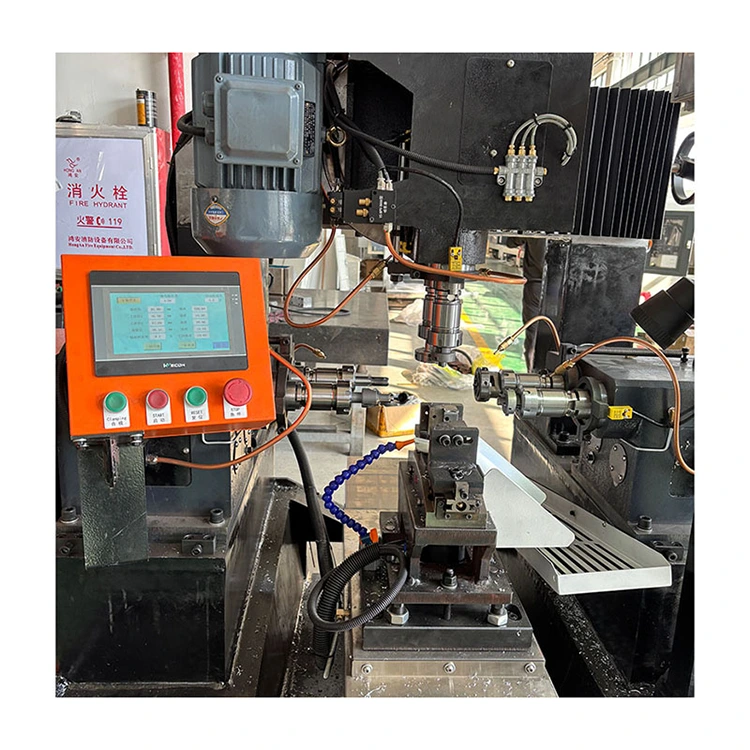

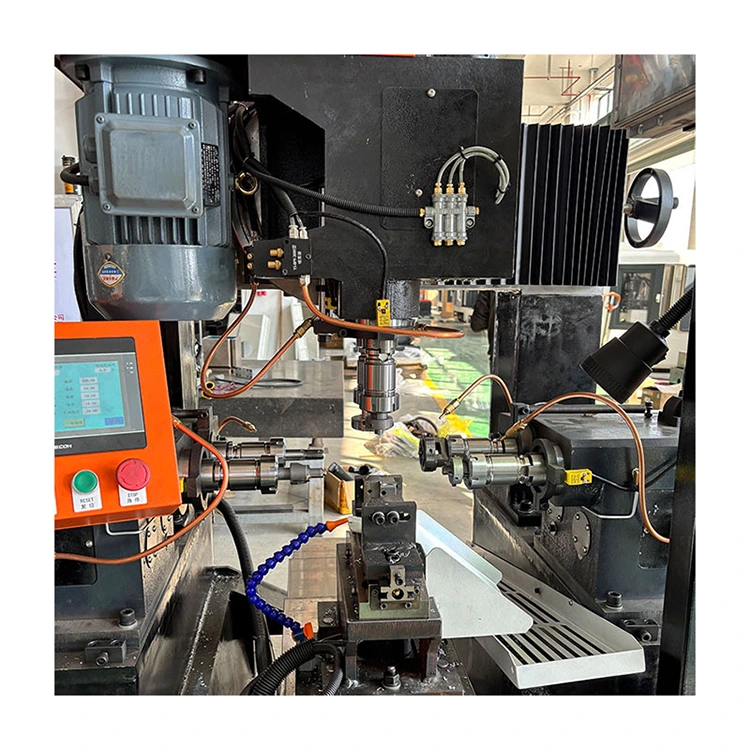

CNC Auto Rotary Drilling Tapping Machine is an intelligent machining center integrating automatic indexing rotation, CNC precision control, drilling and tapping functions. Its core is a precision rotary table (index plate) driven by servo motor, which can automatically and accurately rotate the workpiece to a preset angle. With the high rigidity spindle, the machine tool can automatically complete all the processes of drilling, chamfering and tapping of multiple angles and holes on a workpiece after one clamping according to the programming. It completely solves the complex process of multiple clamping, alignment and machine replacement in traditional processing, and is especially suitable for batch production of flange, end cover, valve body, connecting plate and other disk and box parts.

Why can it be your efficiency multiplier?

1. One-time clamping, complete all hole processing

The traditional method needs to be operated on drilling machine and tapping machine respectively, which is time-consuming and laborious, and the accuracy is difficult to guarantee. Our CNC Auto Rotary Drilling Tapping Machine control the rotary table and spindle through CNC programs to automatically complete all processes in sequence. This not only shortens the processing time by more than 60%, but more importantly, the relative position accuracy of all holes is guaranteed by the machine tool itself, and the consistency is extremely high, which greatly improves the product qualification rate.

2. Strong rigidity, stable tapping quality

For steel and other hard materials tapping easy to break the pain point, we use a large torque servo spindle motor with high rigidity integral casting bed. This design provides stable and sufficient power and rigidity, realizes the true sense of "rigid tapping", ensures smooth thread quality and consistent depth, effectively protects expensive taps, and reduces tool wear costs.

3. High degree of automation

CNC Auto Rotary Drilling Tapping Machine is equipped with an automatic lubrication system and a simplified operator interface. Workers only need to complete the clamping and starting of the workpiece, and the subsequent positioning, tool change, machining and cooling are all automatically completed. One skilled worker can easily manage multiple equipment, significantly reducing dependence on highly skilled workers and labor costs, so that your human resources can be maximized.

4. Good flexibility

By changing fixtures and invoking different CNC programs, CNC Auto Rotary Drilling Tapping Machine can switch to machining another workpiece in minutes. The rotary table has high indexing accuracy and accurate repeated positioning, which is very suitable for flexible production mode of multi-variety and small and medium-sized batches to help you respond quickly to market changes.