- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

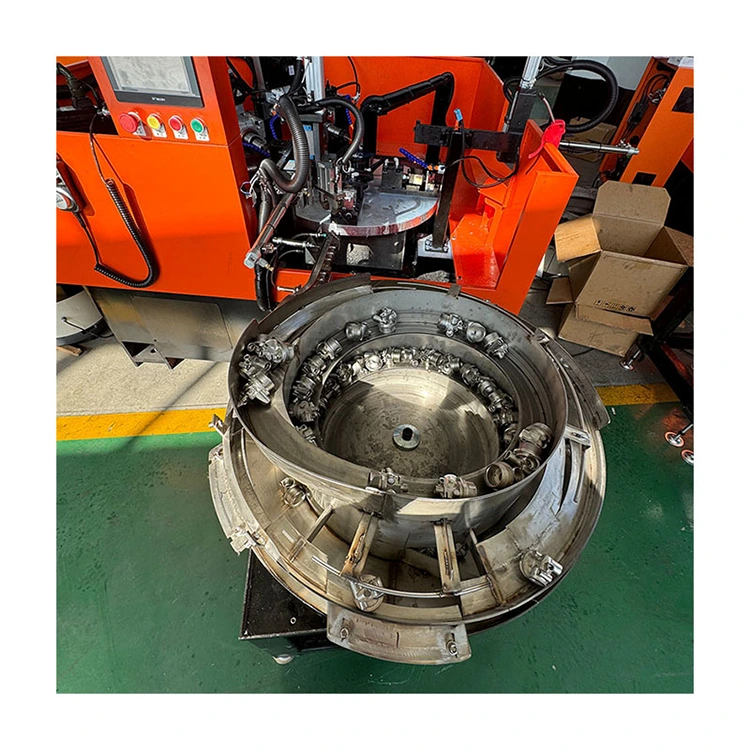

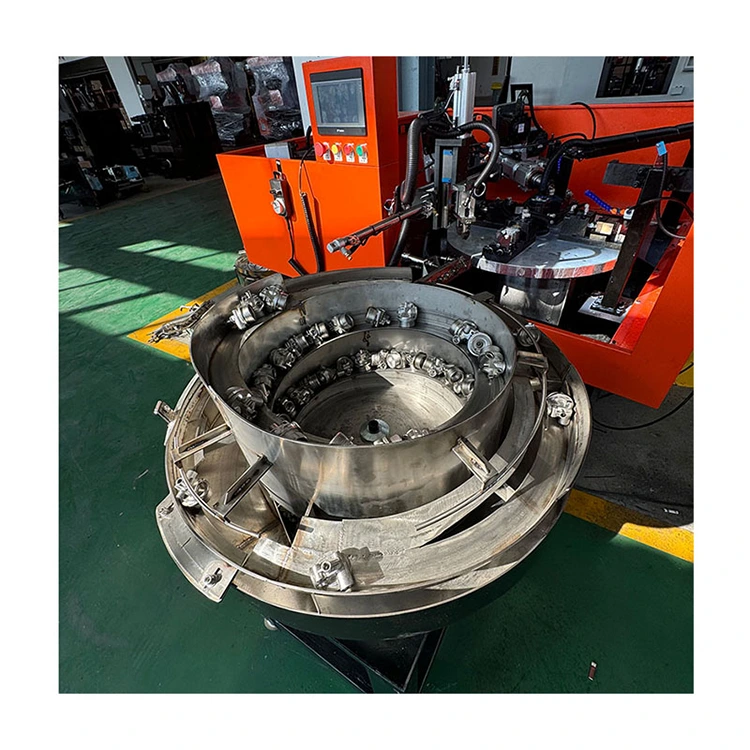

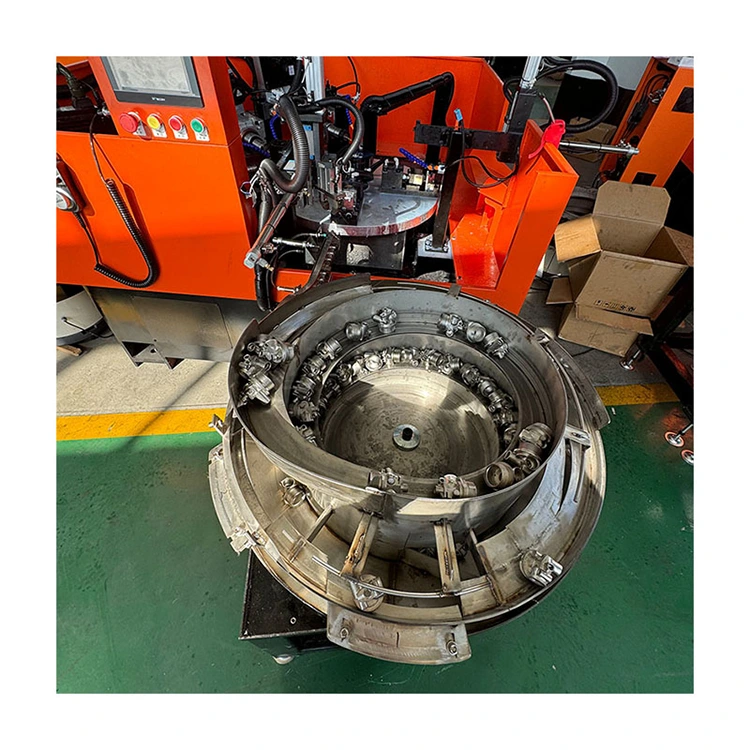

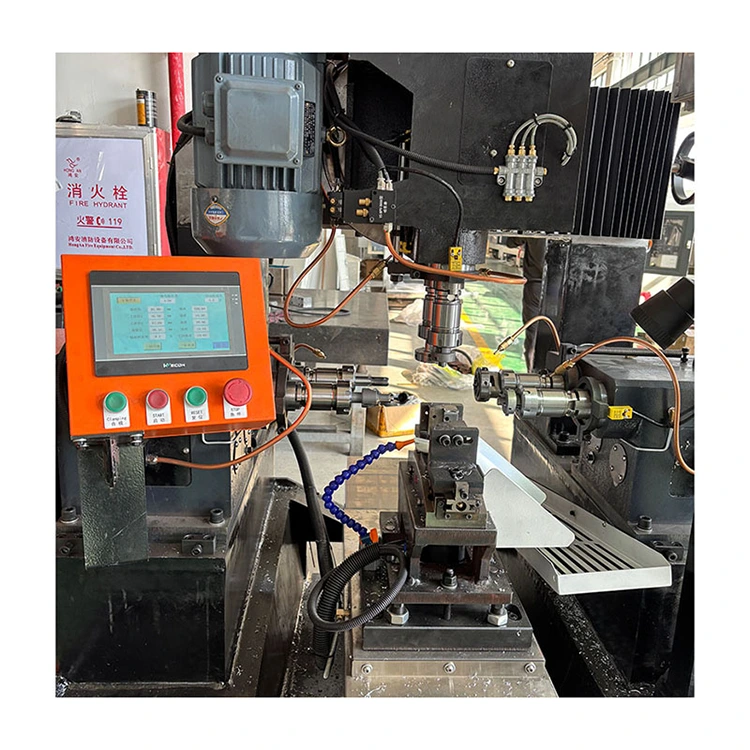

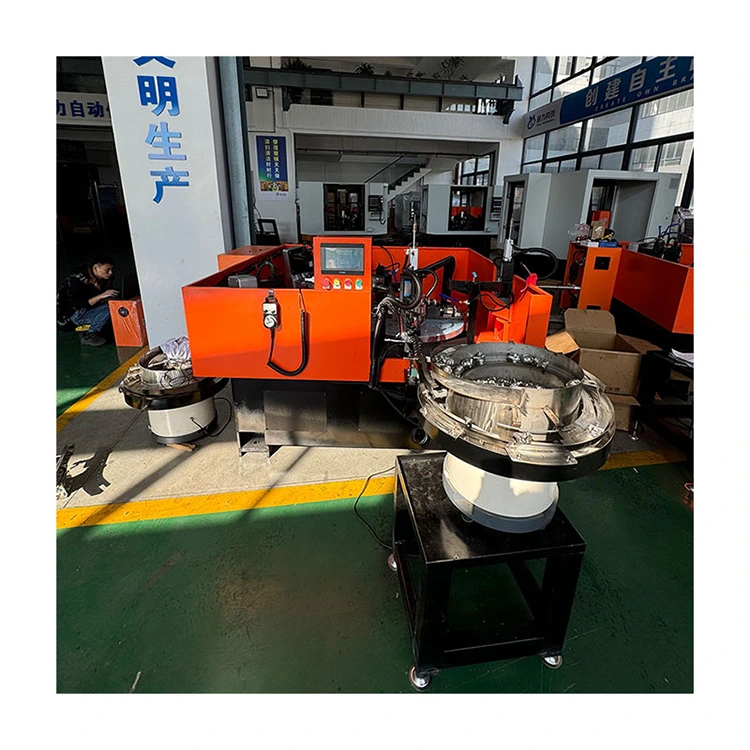

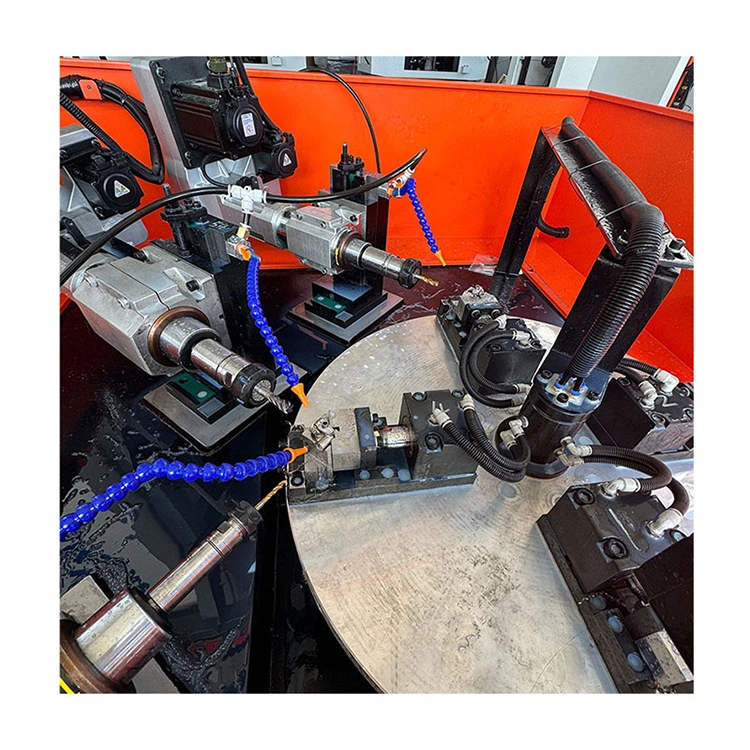

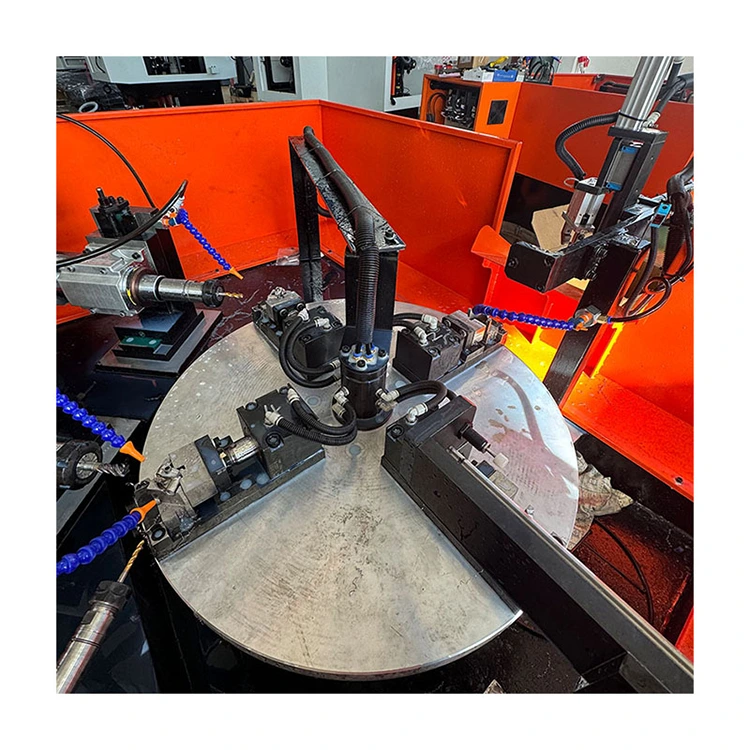

Automatic Nut Tapping Machine

Send Inquiry

As a China supplier in the field of automation equipment, Yueli puts product quality first. This durable Automatic Nut Tapping Machine is based on our many years of field experience and is more than just a machine, it is a complete workstation designed to help you reduce labor costs, increase productivity and ensure consistent thread quality.

What kind of Automatic Nut Tapping Machine is this?

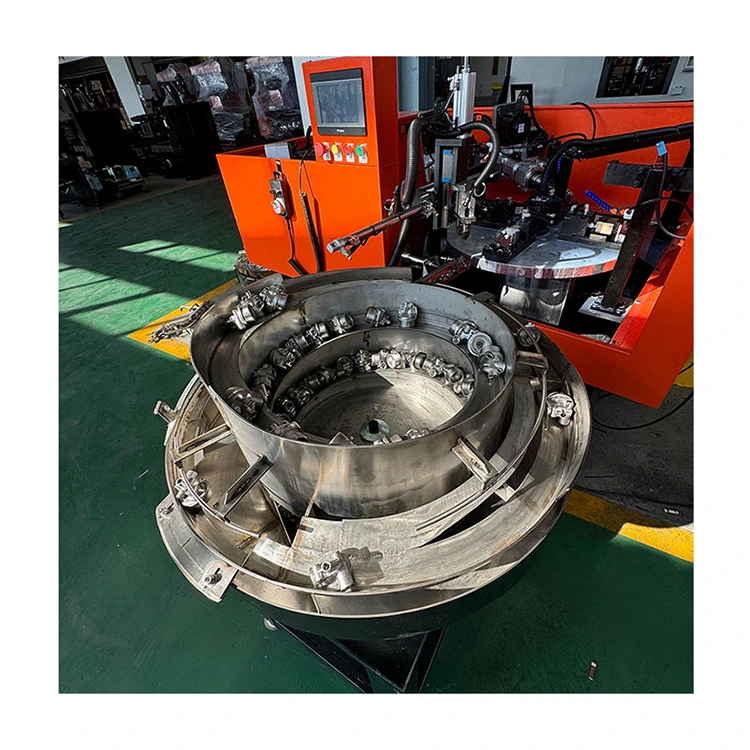

Our Automatic Nut Tapping Machine is an automated machine designed for machining internal threads (tapping) on holed parts such as nuts and flanges. Its core function is to realize the unmanned operation of the whole process from automatic feeding, precise tapping to automatic blanking. You simply dump the parts to be processed into the hopper and the machine delivers a continuous and stable output of finished products like a tireless worker, especially for scenarios where you need to handle large orders.

Product features

1. Automatic operation

Traditional tapping relies on manual operation one by one, which has low efficiency and high labor intensity. Our machines integrate vibrating discs or conveyor mechanisms to achieve automatic sorting and loading; after tapping, the finished product automatically falls into the collection box. One worker can easily take care of multiple machines, freeing you from repetitive work.

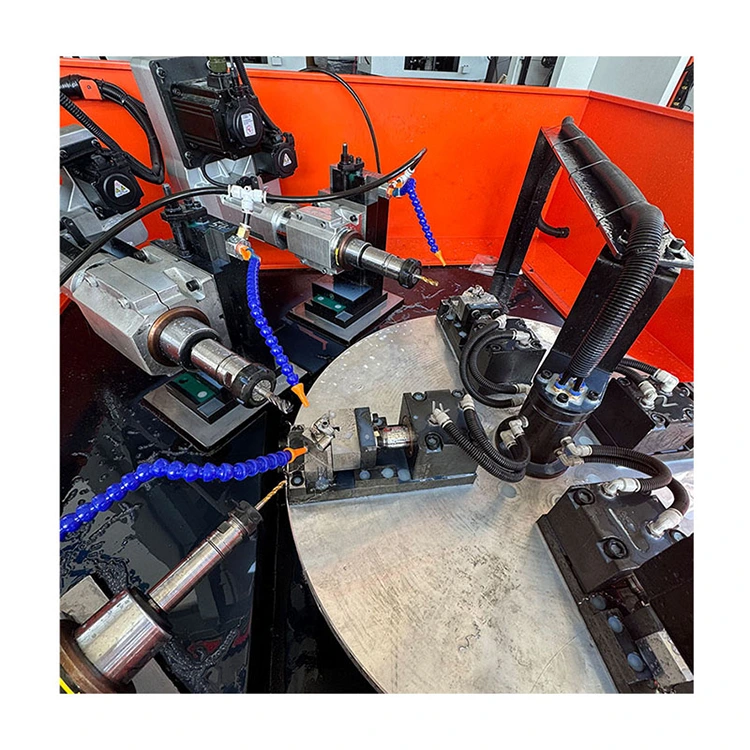

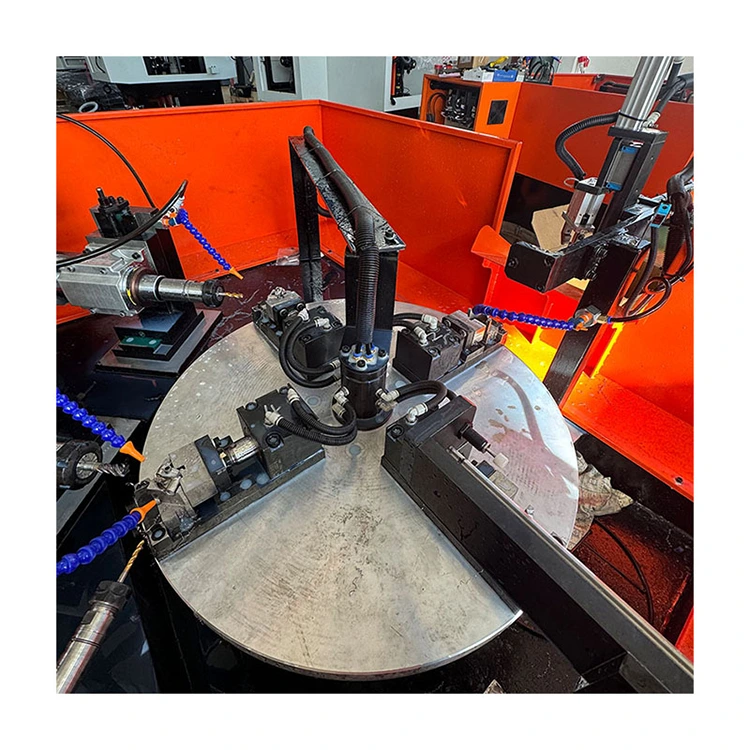

2. Precision stability

Instead of relying solely on electronic sensors that are susceptible to interference, we use highly accurate ratcheting mechanical positioning devices. This mechanical rigid positioning method ensures that the position of each part is accurate and consistent during tapping, thus ensuring the stability of thread depth and verticality, and effectively reducing the defective rate of thread rot and deviation.

3. Firm structure

Automatic Nut Tapping Machine body is welded with thick steel plate, key transmission parts use high quality alloy steel. This design ensures that the machine can still maintain rigidity and stability under 24-hour continuous operation conditions, low failure rate, simple maintenance, and is your reliable partner for long-term stable production.

4. Flexibly customize

We know that different customers processing nut specifications, materials and production requirements vary. Therefore, we not only provide standard models, but also accept custom. Whether it is M3 small nuts or M30 large flanges, whether it is plain carbon steel or stainless steel, we can adjust the equipment parameters and fixtures according to your specific workpiece and rhythm requirements to provide the most suitable solution for you.

Why choose Yueli?

1. Quality guaranteed: Each factory equipment has undergone at least 48 hours of full-load continuous operation testing to ensure that the products delivered to you are stable and reliable.

2. Service follow-up: We provide complete operation instruction videos and graphic manuals. The equipment enjoys a one-year core component warranty and provides life-long technical consulting services. Our engineers can respond quickly through remote video and guide the solution of most problems.

3. Transparent and efficient delivery: standard models are shipped approximately 15-20 business days after order confirmation. Packed in export standard reinforced wooden cases to ensure safe transportation. We encourage and welcome customers to come to our factory for on-site inspection and trial production.

4. Our automatic tapping machine has been widely used in auto parts, hardware fasteners, valve pump body and other industries, and exported to many countries and regions. Customer's continuous repurchase is the best endorsement of our product quality and service.