- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

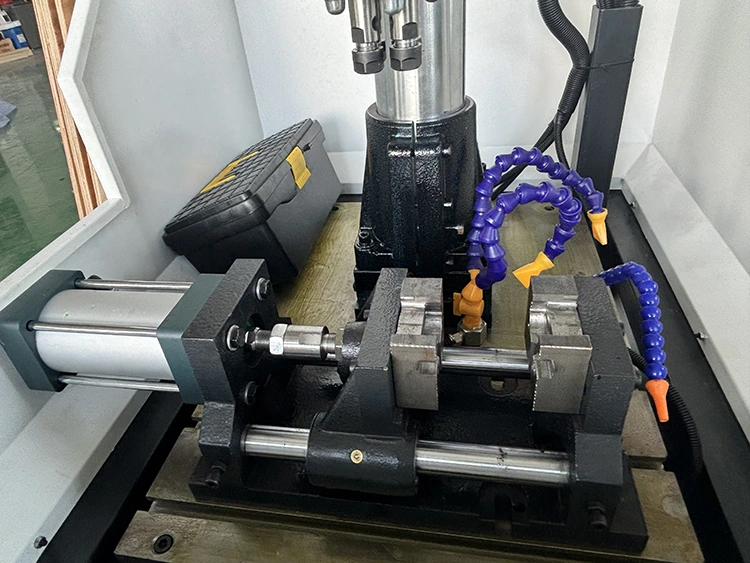

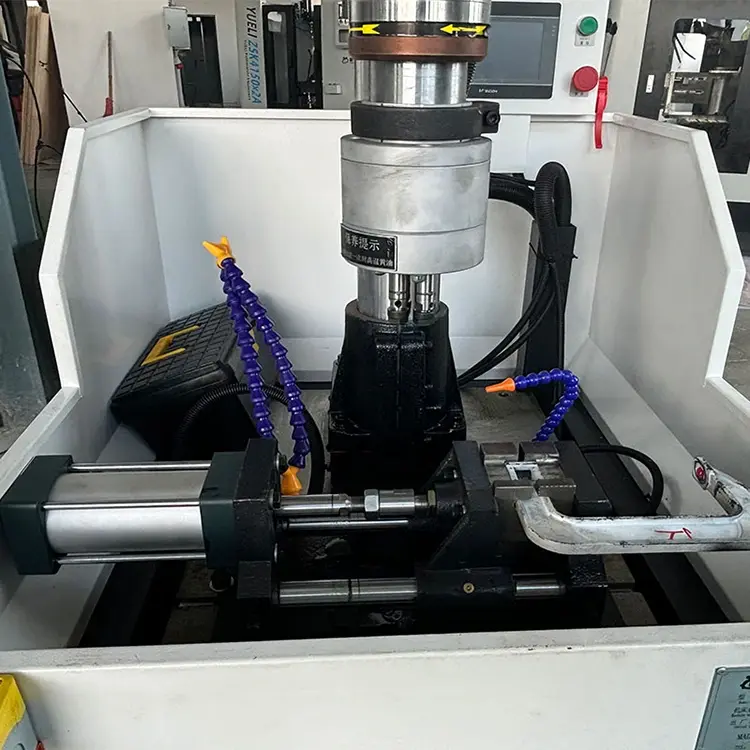

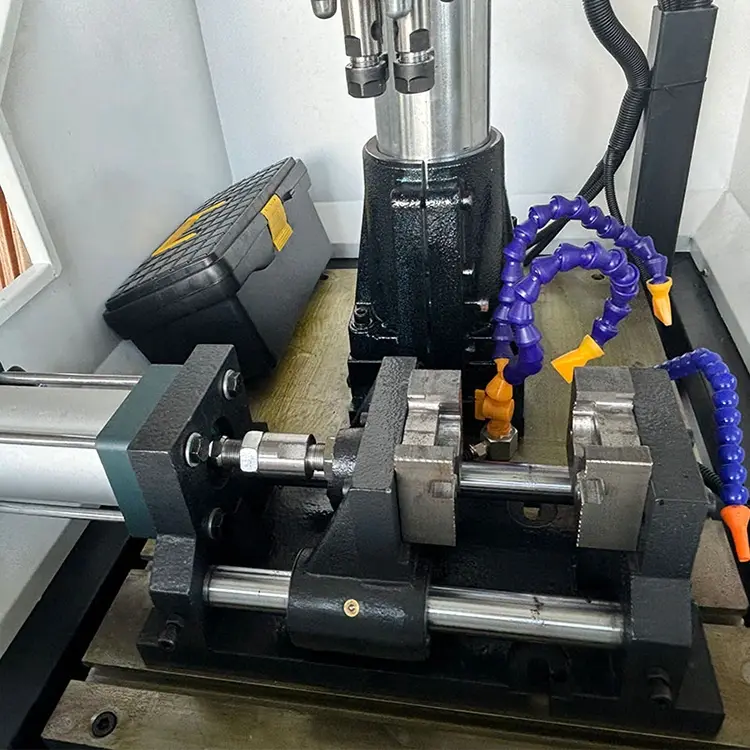

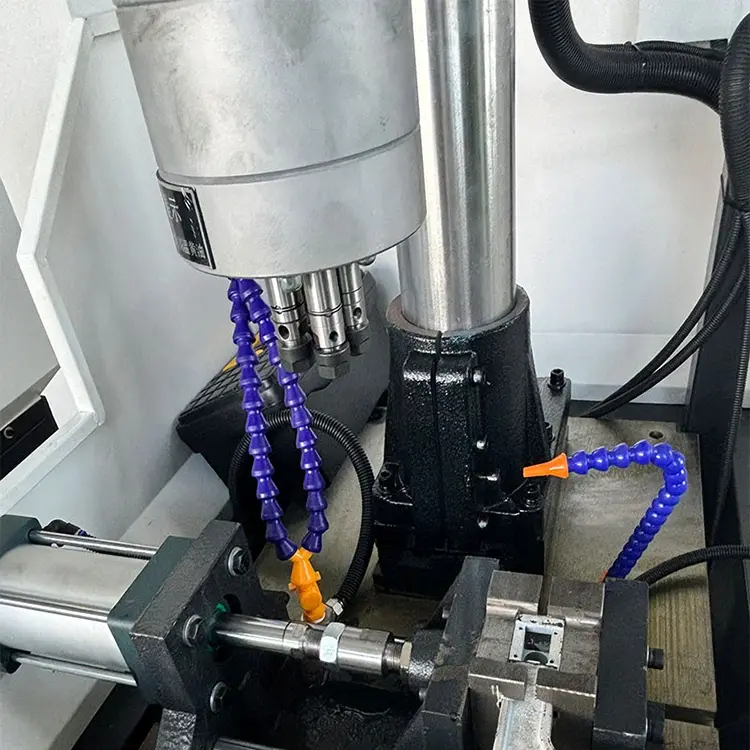

Single Station Auto Drilling Tapping Machine

Send Inquiry

Application Areas

Yueli's high-quality single station auto drilling tapping machine is mainly used for mass production of standardized parts in industries such as automotive, agricultural machinery, construction machinery, and hydraulics/pneumatics. It is used for efficient multi-faceted/multi-hole machining of parts such as engine blocks, valve bodies, and connecting rods, significantly improving the efficiency and consistency of single-part machining.

Key Selling Points

1. High Efficiency

Batch processing or step-by-step processing? Our single station auto drilling tapping machine lets you handle it all at once! Workpieces are clamped once, and drilling, tapping, and milling are automatically completed in multiple positions. Stable precision and high efficiency make it ideal for batch production of automotive/agricultural machinery parts, instantly doubling capacity.

2. Good Adaptability

Standardized parts batch processing overall efficiency? single station auto drilling tapping machine tools are the optimal solution! One clamping completes multiple operations without repeated equipment changes or tooling adjustments. Accuracy ±0.02mm ensures reliable delivery of engine blocks and hydraulic valve bodies, giving factory owners peace of mind!"

3.Our single station auto drilling tapping machine enables multiple processes in one clamping, allowing for efficient batch processing. It also offers stable precision, making it suitable for professional customization industries.

Parameter

| Machining process | A combination of multiple processes including drilling, tapping, milling, and boring |

| Station type | Single station (workpiece is clamped once to complete all processes) |

| Number of spindles | One shaft |

| Spindle speed | 3000rpm |

| Feed rate | 0.1 - 5m/min |

| Repeatability | ±0.02mm |

| Workpiece size | Max Φ200mm×300mm |

| Production efficiency | 10 - 60 pieces/minute (depending on process complexity) |