- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

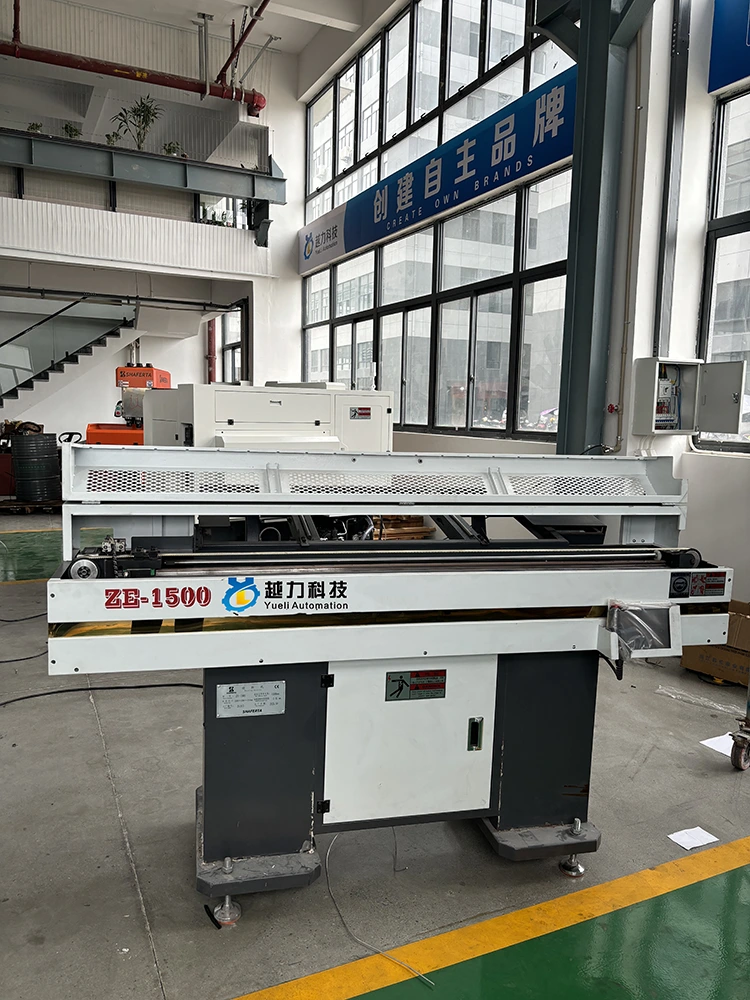

Automatic Bar Feeder

Send Inquiry

The core function of Yuli durable automatic bar feeder is to achieve automatic, continuous, and precise feeding of bar materials. Through an integrated control system, the equipment pushes raw bars to machining centers, such as CNC lathes, according to preset requirements, thereby reducing manual intervention in the production process and supporting continuous automated production. Please contact us anytime for a quote.

Product Features

1. The automatic bar feeder can accommodate bars of various diameters and supports continuous directional feeding of metal bars from p5 to φ30mm, meeting the processing needs of different specifications of materials.

2. The drive system uses a servo motor in conjunction with a PLC control system to achieve precise adjustment of feeding length and speed, ensuring stable and controllable operation.

3. High feeding accuracy, up to ±0.02mm, meeting the stringent requirements of precision machining for bar material feeding position.

4.In terms of structural design, the automatic bar feeder is equipped with a wear-resistant clamping tube and a hydraulically or pneumatically driven feeding mechanism. The machine body has a compact design, which facilitates linkage with equipment such as CNC lathes and supports 24-hour continuous automated production.

Application Areas

The automatic bar feeder is primarily used in bar stock processing in industries such as hardware and automotive parts. Automatic feeding reduces manual intervention, improving processing efficiency and accuracy.

Maintenance Methods

1. To ensure long-term stable operation of the equipment, vulnerable parts must be inspected and replaced regularly. Keep the moving parts of the material conveying mechanism clean and lubricated to prevent impurities from affecting smooth material movement or causing surface wear.

2. The connecting components of the transmission mechanism and the control system should be regularly checked for smooth operation. Timely adjustment of control commands can effectively maintain the accuracy of material conveying and positioning, which is a key maintenance measure to ensure the overall performance of the equipment.

3. The electrical control components should maintain good heat dissipation and grounding. Regularly check the tightness of the wiring terminals and the integrity of the signal lines.

4. If abnormal vibration or noise is detected, the machine should be stopped immediately for inspection of the transmission components and clamping mechanism to prevent the fault from escalating and causing production interruption.

How does the Automatic Bar Feeder ensure stable feeding accuracy?

Our automatic bar feeder uses a servo motor drive and PLC control system. Through a closed-loop feedback mechanism, the feeding position is adjusted in real time. Meanwhile, wear-resistant parts and a robust structural design reduce deviations during operation, thus ensuring stable feeding accuracy over long-term use.