- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Core Sampling Outside The Skid Steer

Send Inquiry

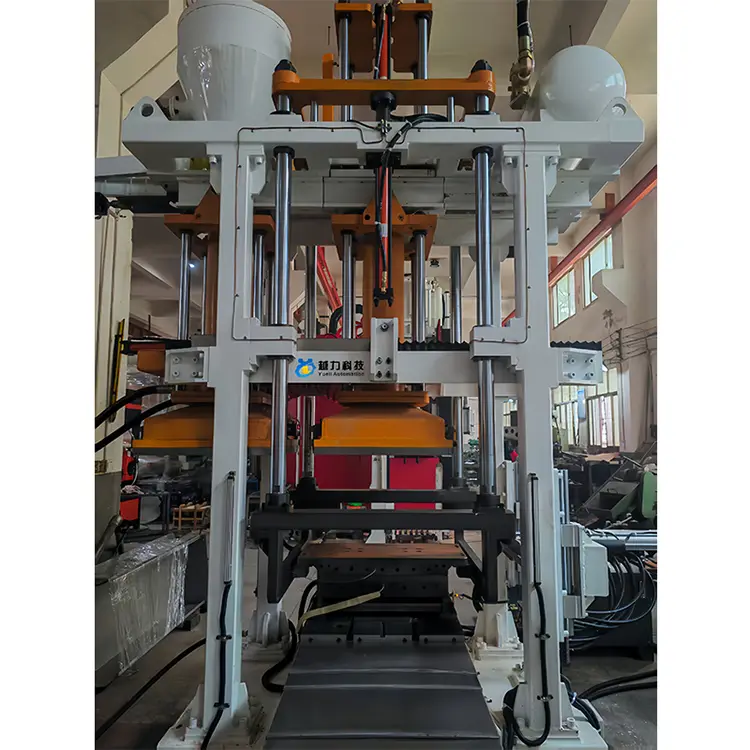

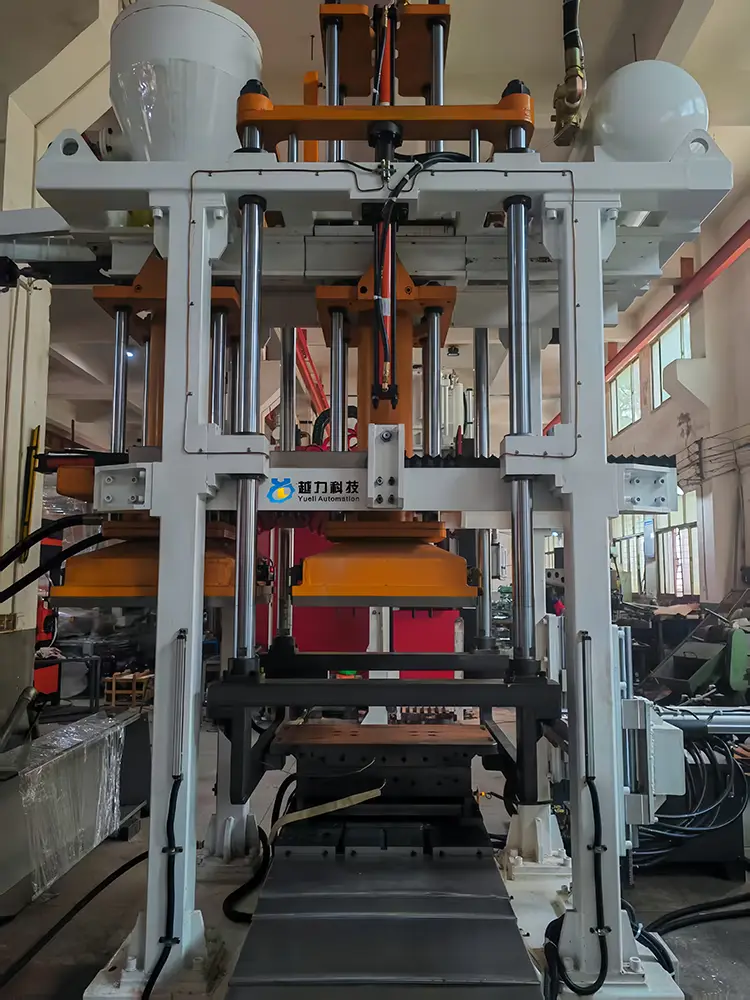

High-end fully automatic cold core box core shooting machine. Horizontal mold parting

|

Equipment model |

YL1080H-40A Core sampling outside the skid steer |

|

Device name |

Fully automatic cold core box core injection machine. Horizontal classification |

|

Device attributes |

Excellent vertical sandblasting. Horizontal parting of the mold |

|

Manufacturer |

The "Yueli" brand of Fujian Province |

◆Equipment Introduction:

[Fully Automatic Cold Core Box Core Shooting Machine. Horizontal Mold Parting]

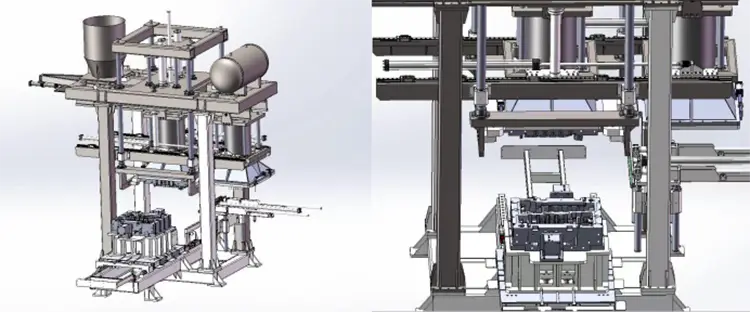

YL1080H-40A Fully automatic cold core box core Shooting Machine [Excellent vertical sand shooting. "Horizontal parting of mold.

Programmable PLC program control system. Servo precision hydraulic system. Core removal from the outside of the linear guide sliding machine. Elevator induction sand addition

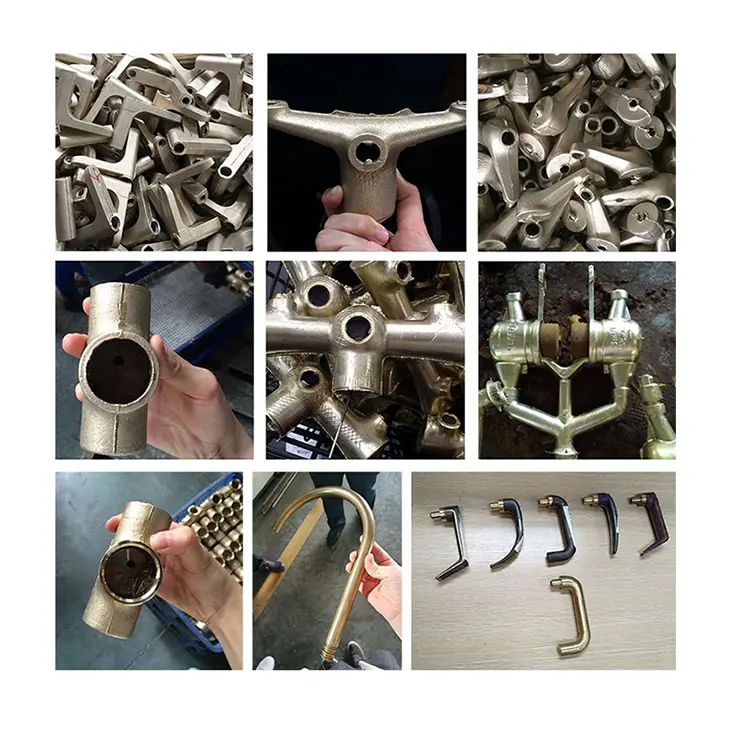

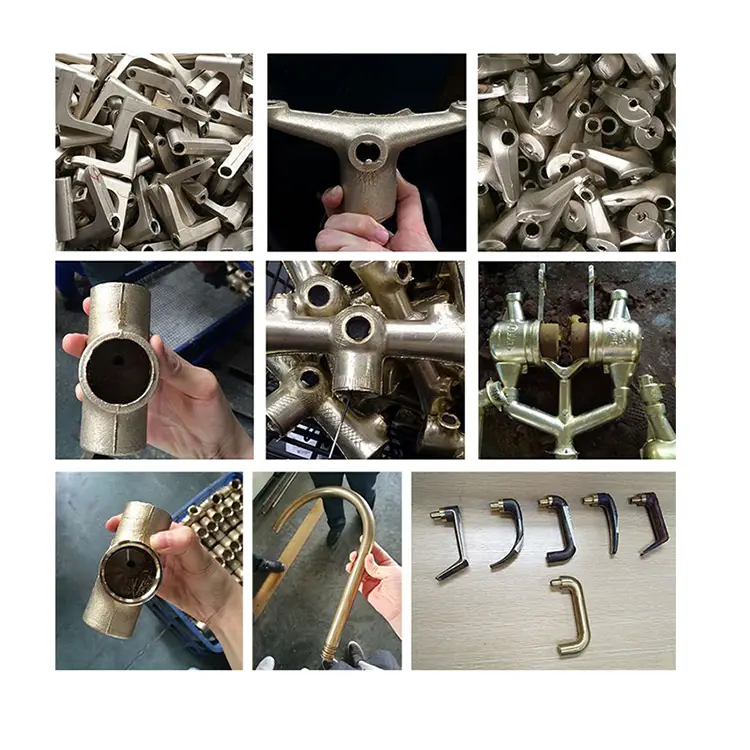

The fully automatic cold core core shooting machine (horizontal mold parting) also features excellent vertical sand shooting. Horizontal parting of the mold. The precision linear guide of the lower mold is removed for core taking. The intelligent sensing sand addition machine, fully automatic/manual operation cold core box core-making equipment, works on the principle of injecting the mixed raw sand into the core box, blowing gas and then rapidly hardening, thereby achieving a tight and smooth surface. High-quality sand core shell core products with precise dimensions are widely used in industries such as valve fire protection, cast iron shell mold stack casting, and precision casting of new energy aluminum alloys.

◆Main equipment specifications and models

①YL660H-25A ②YL870H-25A ③YL1080H-40A ④YL1210H-50A ⑤YL1512H-50A

◆ Main equipment functions [YL1080H-40A cold core. "Core sampling outside the skid steer.

1. Excellent vertical sandblasting. Horizontal parting of molds. German Siemens control system

2. Inovance servo precision hydraulic system, Taiwan Airtac precision pneumatic system

3. The core is taken from the outside of the precision linear guide sliding machine of the lower die, and the intelligent sensing sand addition machine is used

4. High-end environmentally friendly casting machine, with an integrated smoke and dust removal design for the overall equipment panel

◆ Main equipment technical parameters [YL1080H-40A cold core] "Core sampling outside the skid steer.

| 1. Maximum sand mold weight | 50kg per mold (sand injection volume) |

| 2. Maximum mold size | 1000×800×700mm |

| 3. Dimensions of the mold mounting plate | 1000×800mm [Effective mold installation space] |

| 4. Effective sandblasting range | 860×660mm (with sand cleaning device) |

| 5. The stroke of the pressure head pressing cylinder is φ80×2 | ≤500mm [Servo precision hydraulic] |

| 6. The stroke of the clamping cylinder is φ80×2 | ≤500mm [Servo precision hydraulic] |

| 7. Maximum mold opening space | 900mm |

| 8. Minimum mold closing space | 400mm |

| 9. Sand storage capacity of the sand hopper | 300kg |

| 10. Triethylamine generator | DZ-40A |

| 11. Equipment voltage | Three-phase Ac380V.50Hz |

| 12. Driving mode | Servo precision hydraulic system + pneumatic |

| 13. Core sampling method | Core removal outside the lower die linear guide sliding machine/mold installation outside the machine |

| 14. Top mold type: φ80×80mm | ≤80mm [Servo precision hydraulic. The itinerary is adjustable |

| 15. Net weight of the equipment | 9000kg |

| 16. Equipment dimensions | 4000×3300×3600mm |

◆ Sand mold product display [YL1080H-40A cold core. "Core sampling outside the skid steer.

◆ Equipment working procedure [YL1080H-40A cold core. "Core sampling outside the skid steer.

Lower mold entry → Mold closing [downward pressure] → Combination module entry [core-pulling module] → Sand injection head entry → Sand injection head downward pressure → Sand injection → Sand injection head exhaust → Sand injection head rise → sand injection head retract (reset)/Air injection head entry → Sand injection head loading/mold

Sand scraping (cleaning sand) → downward pressure of the air injection head → Air injection → solidification of the sand core → retraction of the combined module (core removal and reset) → top mold (sand mold remaining in the mold) → first mold opening 20-50mm (sand core demolding) → second mold opening/air injection head rising → lower mold sliding out (reset)/sand injection head entering → lower mold top core (sand core demolding) → core removal outside the machine →⒆ safe core removal time →⒇ lower mold Reset the top core

◆ Equipment configuration [YL1080H-40A cold core. "Core sampling outside the skid steer.

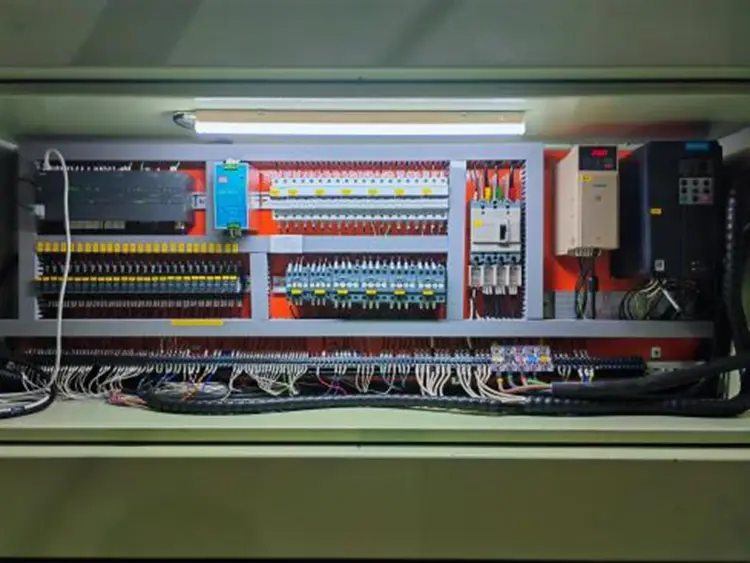

1. Electrical control system: High-end operation electrical control system from Siemens of Germany (touch screen and program split type)

Siemens series high-end switch buttons [start button, rotary gear switch]

2. Hydraulic system: Huichuan servo precision stepless speed change hydraulic system, Taiwan brand hydraulic components

3. Pneumatic System: Taiwan Airtac Precision Pneumatic System [Cylinders. Electromagnetic valve. Air source processor

4. Atomization system: Pure imported Japanese SMC precision atomization treatment system. SMC core pneumatic components

5. Low-voltage electrical appliances: Snyder low-voltage electrical appliances. Omron proximity switch. Taiwan Mingwei power switch

5. Safety Control: The moving parts of the opening and closing mold are equipped with inductive safety light curtains

6. Lubrication System: The main moving parts of the opening and closing mold are equipped with an automatic oil injection lubrication system

7. Pressure display: The action pressure of the equipment and the sand shooting pressure are displayed independently

8. Equipment appearance: Powder coating and baking varnish. High-end paint surface treatment

◇ Other detailed configurations:

[1] PLC touch screen: Siemens, Germany

[2] Program center processor: Siemens, Germany

[3] Push-button switch: Siemens, Germany

[4] AC contactor: Schneider

[5] Relay: Schneider

[6] Proximity switch Omron

[7] Switching power supply: Mingwei, Taiwan

◆ Main features and advantages of the equipment [YL1080H-40A cold core. "Core sampling outside the skid steer.

◇ Precision and Stability: The overall structure of the YL1080H-40A cold core core shooting machine adopts a high-standard mechanical structure design principle of precision and stability, with excellent and strict manufacturing processes. It uses high-precision precision processing equipment, and the structure of the moving parts is highly precise. The entire machine structure is stable and durable for a long time.

◇ Excellent sandblasting: The YL1080H-40A cold core sandblasting machine features an excellent vertical sandblasting method, relying on the pressure-holding shooting of the equipment

The principle of sand and the natural gravitational effect of resin sand; The mold is equipped with a rapid and smooth exhaust method on three sides simultaneously. The core-making process can fill the mold cavity in the shortest time. The sand core is tight, full and smooth, and the core-making yield is high.

◇ Intelligent and efficient: The YL1080H-40A cold core core shooting machine features a high degree of automation. It is equipped with precise linear guides for removing cores from the lower mold, making core removal easy and highly automated. It enables one person to operate multiple machines, ensuring stability, smoothness, efficiency and safety.

High yield rate: The YL1080H-40A cold core core shooting machine features an excellent vertical sand shooting method, high-end precision mechanical structure, high sealing performance, strong sand shooting force, tight and smooth sand cores, precise dimensions, and high-quality sand cores with a high yield rate. It can effectively control the machining allowance of castings.

◇ High-end environmental protection: The YL1080H-40A cold core core injection molding machine adopts the high environmental protection standards for casting machines. During the equipment design process, the high environmental protection requirements for smoke and dust during the production process were comprehensively and meticulously considered. The smoke and dust were uniformly integrated for treatment, and the designed high environmental protection casting machine effectively improved the environment of the casting workshop.

◇ Exquisite and Durable: The design process of the YL1080H-40A cold core core shooting machine has fully taken into account the service life of the equipment. Different components are manufactured with high standards and reasonable materials based on different usage requirements. The heat treatment requirements and appearance details are well handled, ensuring that the equipment can maintain its precision for a long time, remain stable and smooth, and have exquisite details.

◇ Applicable materials: Shot dry sand [dry phenolic resin sand]

◆ Equipment Operation and Use:

(1) Check whether the air intake pipe and power supply (three-phase 380V, 50Hz) have been properly connected.

(2) Remove the dust on the equipment after installation. Tools and other sundries.

⑶ Whether the equipment is in the initial position when the mold is opened to ensure the safety of the operators.

⑷ Install the mold (core box) on the machine; Under any circumstances, before opening the air valve (supplying air to the equipment), the installation rod should be pushed into the space between the machine worktable and the sand injection head to avoid damage and ensure personnel safety.

⑸ Close the main power switch and all control circuit switches, and check the lighting work lights. Check if the power signal light on the control panel is normal.

(6) Open the main intake valve and check whether the air pressure in the air pipe is within the normal range of 6 to 7Kpa.

Switch the machine's operation mode to manual mode and manually debug whether each moving part of the machine operates smoothly and normally.

Whether the mold opening and closing actions are smooth or not, set a reasonable mold opening and closing time according to the characteristics of the mold

② Check whether the advance and retreat actions of the combined module are smooth. Set reasonable advance and retreat times based on the module's travel

③ Whether the advance and retreat actions of the sand shooting head are smooth or not, set a reasonable advance and retreat time according to the stroke of the sand shooting head

④ Whether the sandblasting operation is normal or not, set a reasonable sandblasting time according to the characteristics of the mold for the sandblasting work

⑤ Whether the exhaust of the sand injection head is working properly is generally set at 8 to 10 seconds for the sand box exhaust time

⑥ Whether the advance and retreat actions of the lower mold are smooth or not, set a reasonable advance and retreat time according to the stroke of the lower mold

⑦ Check whether the ejector action is normal and the core is working properly. Set a reasonable core ejector time according to the characteristics of the mold

⑧ Switch the operation mode to single operation, and the machine will automatically cycle and run several times without load. Check whether all the actions of the machine are coordinated, orderly, stable and smooth.

◆ Precautions during the operation process:

Before the test run, it is necessary to remove the dust on the machine and clear away any tools or other debris left on it to prevent malfunctions during operation.

Before starting the operation, it is necessary to carefully check the condition of the bolts in all parts of the machine and ensure they are tightened.

⑶ Before starting the operation, check whether all the moving parts are in the initial normal position.

⑷ In case of machine failure, it should be stopped immediately, the stop button pressed, the power and gas supply cut off, and maintenance carried out. ⑸ It is necessary to frequently check whether the electrical circuit joints are loose and whether the machine components are damaged.

(6) Non-professionals are not allowed to open the electrical control cabinet at will or place any miscellaneous items inside.

One must undergo training and be familiar with the machine's structure, working principle and operation rules before being allowed to operate it. No one else is permitted to operate the machine at will.

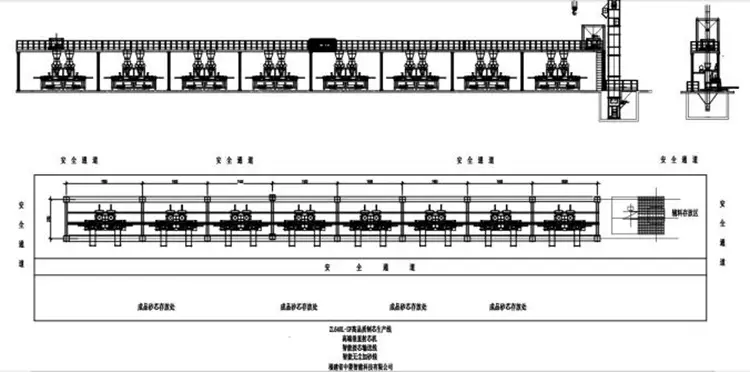

◆ High-quality fully automatic vertical core shooting machine production line:

Case features:

① High-quality, high-intelligence and high-environmental protection casting machine. The entire panel integrates smoking and dust removal functions.

② Intelligent continuous core connection for conveyor belts. The equipment has a high degree of automation. Save labor

③ Elevator + precision track intelligent sensing sand addition. The workshop is efficient, convenient and clean

④ The overall environmental protection system of the core-making workshop. High-efficiency smoking and dust removal. Workshop environmental protection standards

⑤ core-making area data storage and output. Realize the digitalization of chip manufacturing. Information-based management.